|

32 Ø |

40 Ø |

50 Ø |

63 Ø |

80 Ø |

100 Ø |

125 Ø |

160 Ø |

200 Ø |

250 Ø |

300 Ø |

|

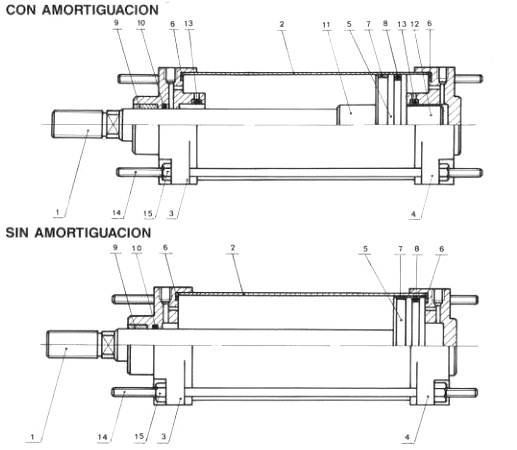

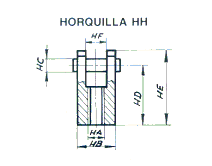

| A |

12 |

18 |

22 |

30 |

40 |

60 |

|||||

| B CNOMO |

M-10X15 |

M-16X1,5 |

M-20X1,5 |

M-27X2 |

M-36X2 |

M-50X3 |

|||||

| B CETOP |

M-10X1,5 |

M-12X1,25 |

M-16X1,5 |

M-20X1,5 |

M-24X2 |

M-36X2 |

M-50X3 |

||||

| B ISO |

M-10X1,5 |

M-12X1,25 |

M-16X1,5 |

M-20X1,5 |

M-27X2 |

M-36X2 |

M-50X3 |

||||

| C |

25 |

32 |

45 |

55 |

65 |

102 |

|||||

| CH |

8 |

13 |

17 |

22 |

32 |

47 |

|||||

| D |

M-6 |

M-8 |

M-10 |

M-12 |

M-16 |

M-20 |

M-24 |

||||

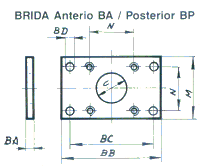

| E CNOMO |

20 |

36 |

45 |

63 |

85 |

70 |

|||||

| E CETOP |

20 |

24 |

32 |

40 |

48 |

72 |

70 |

||||

| E ISO |

22 |

24 |

32 |

40 |

54 |

72 |

70 |

||||

| F CNOMO |

10 |

19 |

19 |

27 |

25 |

30 |

|||||

| F CETOP ISO |

9 |

13 |

20 |

15 |

22 |

27 |

41 |

55 |

65 |

30 |

|

| G |

15 |

20 |

25 |

48 |

|||||||

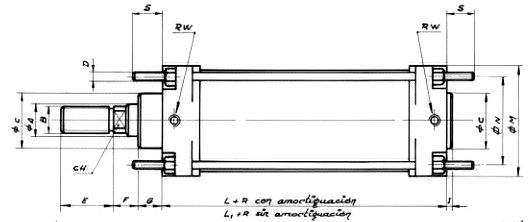

| RW |

1/8 |

1/4 |

3/8 |

1/2 |

1/2 |

3/4 |

|||||

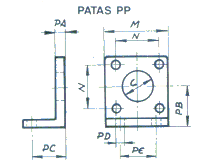

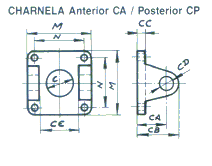

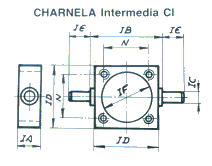

| M |

45 |

52 |

65 |

75 |

95 |

115 |

140 |

180 |

220 |

270 |

320 |

| N |

33 |

40 |

49 |

59 |

75 |

90 |

110 |

140 |

175 |

208 |

260 |

| L + R CNOMO |

80 |

110 |

125 |

145 |

180 |

231 |

|||||

| L + R CETOP ISO |

98 |

110 |

125 |

136 |

145 |

168 |

180 |

190 |

231 |

||

| L1 + R |

64 + R |

78 + R |

76 + R |

93 + R |

102 + R |

152 |

|||||

| S |

17 |

23 |

28 |

34 |

43 |

70 |

|||||