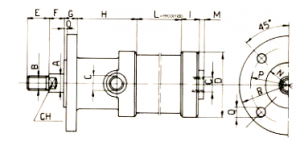

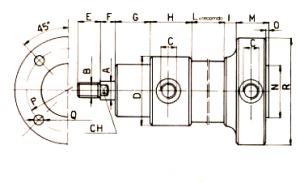

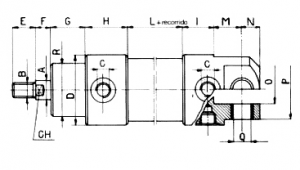

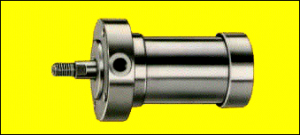

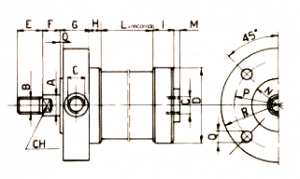

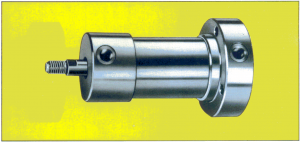

General features

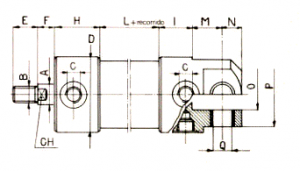

This series include small

medium diameters:

|

Diameter |

Exit Flow |

|

20 |

1/8’’ gas |

|

27 |

1/8’’ gas |

|

35 |

1/8’’ gas |

|

40 |

1/8’’ gas |

|

50 |

1/8’’ gas |

|

58 |

1/4’’ gas |

|

70 |

1/4’’ gas |

|

85 |

1/4’’ gas |

|

100 |

1/4’’ gas |

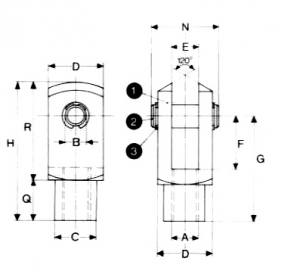

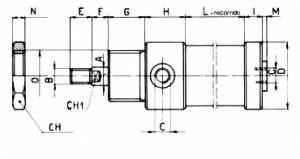

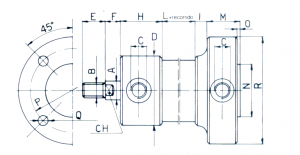

This device has got three parts rod clevis:

This device has got three parts rod clevis: