If you need a fully guaranteed quality impact cylinder, we can offer you the best solutions. At Inprone we specialize in the development and manufacture of pneumatic impact cylinders.

If you need a fully guaranteed quality impact cylinder, we can offer you the best solutions. At Inprone we specialize in the development and manufacture of pneumatic impact cylinders.

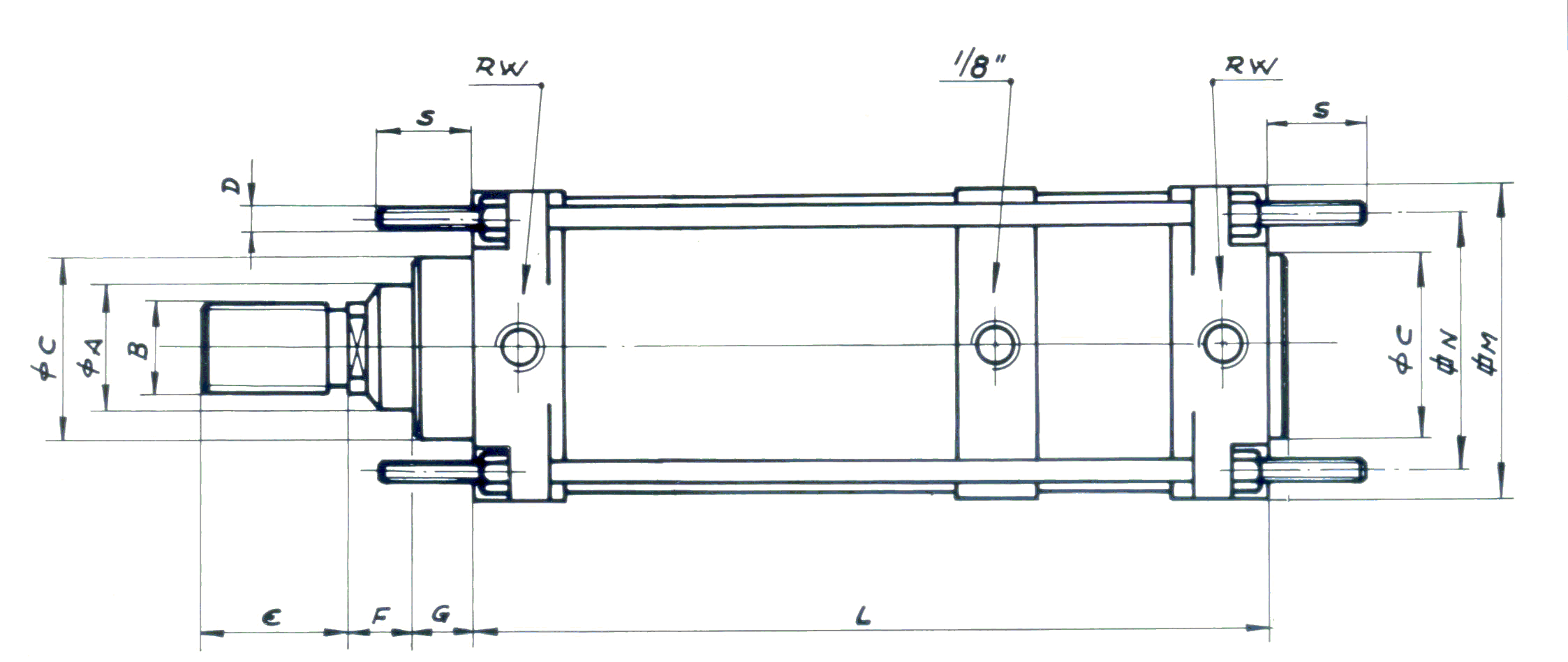

|

I / 32 |

I / 40 |

I / 50 |

I / 63 |

I / 80 |

I / 100 |

I / 125 |

I / 160 |

I / 200 |

|

|

A |

16 |

18 |

22 |

30 |

40 |

||||

|

B |

M-12 X 1,75 |

M- 16 X 1,5 |

M- 20 X 1,5 |

M- 27 X 2 |

M- 36 X 2 |

||||

|

C |

25 |

32 |

45 |

55 |

65 |

||||

|

D |

M-6 |

M-8 |

M-10 |

M-12 |

M-16 |

||||

|

E |

20 |

36 |

46 |

63 |

85 |

||||

|

F |

10 |

19 |

27 |

||||||

|

G |

15 |

20 |

25 |

||||||

|

Rw |

1/8″ G |

1/4″ G |

3/8 G |

1/2″ G |

3/4″ G |

||||

|

M |

45 |

52 |

65 |

75 |

95 |

115 |

140 |

180 |

220 |

|

N |

32 |

40 |

49 |

59 |

75 |

90 |

110 |

140 |

175 |

|

L |

137 |

195 |

220 |

270 |

360 |

||||

|

S |

17 |

17 |

23 |

23 |

28 |

28 |

34 |

50 |

50 |

|

Stroke |

38 |

60 |

70 |

80 |

130 |

||||

|

|

480 kg |

750 kg |

1.200 kg |

1.860 kg |

3.000 kg |

4.700 kg |

7.500 kg |

12.000 kg |

18.000 kg |

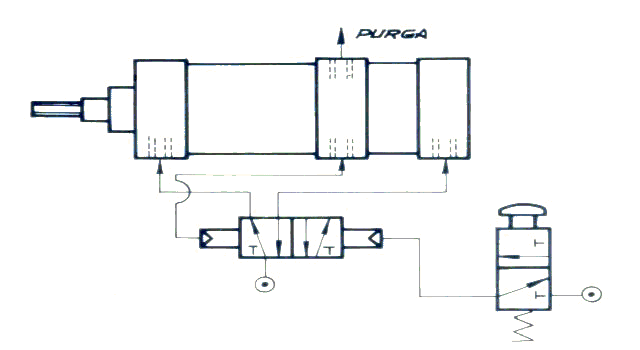

NOTE:

Cylinder assembly is the same as that of a normal thrust cylinder.

The main body has two 1/8 gas orifices. One of them leads to the exterior, that is, it is a continuous blow through. The other one is for piloting the 5-way valve so that the impact cylinder moves back to place.

It is used in all cases requiring elevated impact force with a small cylinder, such as riveting, punching, cutting, sealing, etc.

The impact cylinder transforms a force of 6 kg/cm² into 60 kg/cm² practical force, approximately between 20 and 80 mm of stroke length depending on size.

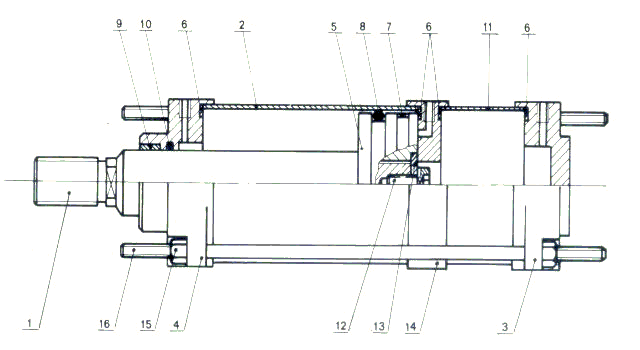

1.- Rod

2.- Front tube

3.- Rear cover

4.- Tapa delantera

5.- Piston

6.- Flat seat seals

7.- Guide seal

8.- Piston seal

9.- Rod bushing

10.- Rod seal

11.- Rear tube

12.- Impact seal fastening screw

13.- Impact seal

14.- Main body

15.- Brace nuts

16.- Braces