Do you need a pressure multiplier? If so, in Inprone we can put in your hands the highest quality products. We will advise you on the models that best suit your needs.

Do you need a pressure multiplier? If so, in Inprone we can put in your hands the highest quality products. We will advise you on the models that best suit your needs.

Air/Oil and Air/Air boosters with unique elements designed by INPRONE, based on CNOMO series cylinders without cushioning.

Although this catalogue contains 26 models, they can be built in any other size or intensification ratio.

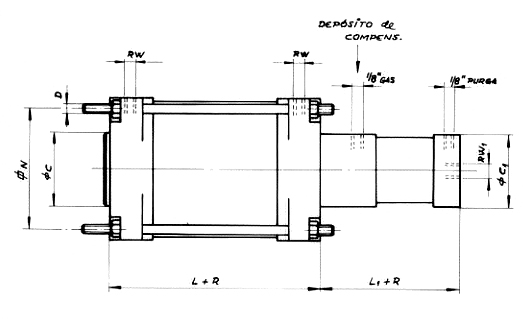

For calculation purposes all the boosters come with a common 100 mm stroke. They are divided into three families according to a combination of diameters

|

1.ST FAMILY |

(1) CM³ |

(2) Kcm² |

N |

C |

C,D |

D |

Rw |

L + R |

| M 50 + 18/100 |

25 |

46 |

49 |

32 |

30 |

M-8 |

1/4’’ G |

78 + R |

| M 80 + 22/100 |

38 |

79 |

75 |

45 |

35 |

M-10 |

3/8’’ G |

76 + R |

| M 125 + 30/100 |

70 |

104 |

110 |

55 |

50 |

M-12 |

1/2’’ G |

93 + R |

| M 200 + 40/100 |

125 |

150 |

175 |

65 |

60 |

M-16 |

3/4’’ G |

102 + R |

| M 300 + 60/100 |

282 |

150 |

260 |

102 |

82 |

M-24 |

1’’ G |

231 + R |

|

2nd.FAMILY |

||||||||

| M 50 + 12/100 |

11 |

104 |

49 |

32 |

30 |

M-8 |

1/4’’ G |

78 + R |

| M 80 + 12/100 |

11 |

266 |

75 |

46 |

30 |

M-10 |

3/8’’ G |

76 + R |

| M 80 + 18/100 |

25 |

118 |

75 |

45 |

30 |

M-10 |

3/8’’ G |

76 + R |

| M 125 + 18/100 |

25 |

189 |

110 |

55 |

30 |

M-12 |

1/2’’ G |

93 + R |

| M 125 + 22/100 |

38,27 |

193 |

110 |

55 |

35 |

M-12 |

1/2’’ G |

93 + R |

| M 200 + 30/100 |

70 |

266 |

175 |

65 |

60 |

M-16 |

3/4’’ G |

102 + R |

| M 300 + 40/100 |

125 |

337 |

260 |

102 |

75 |

M-24 |

1’’ G |

152 + R |

| M 300 + 50/100 |

196 |

216 |

260 |

102 |

82 |

M-24 |

1’’ G |

152 + R |

|

3rd.FAMILY |

||||||||

| M 50 + 22/100 |

38 |

30 |

49 |

32 |

35 |

M-8 |

1/4’’ G |

78 + R |

| M 50 + 30/100 |

70 |

16 |

49 |

32 |

50 |

M-8 |

1/4’’ G |

78 + R |

| M 80 + 30/100 |

70 |

42 |

75 |

45 |

50 |

M-10 |

3/8’’ G |

76 + R |

| M 80 + 40/100 |

125 |

24 |

75 |

45 |

50 |

M-10 |

3/8’’ G |

76 + R |

| M 125 + 40/100 |

125 |

58 |

110 |

55 |

60 |

M-12 |

1/2’’ G |

93 + R |

| M 125 + 50/100 |

196 |

37 |

110 |

55 |

75 |

M-12 |

1/2’’ G |

93 + R |

| M 125 + 60/100 |

282 |

26 |

110 |

55 |

82 |

M-12 |

1/2’’ G |

93 + R |

| M 200 + 60/100 |

282 |

66 |

175 |

65 |

82 |

M-16 |

3/4’’ G |

102 + R |

| M 200 + 80/100 |

502 |

37 |

175 |

65 |

98 |

M-16 |

3/4’’ G |

102 + R |

| M 200 + 100/100 |

785 |

24 |

175 |

65 |

140 |

M-16 |

3/4’’ G |

102 + R |

| M 300 + 80/100 |

502 |

84 |

260 |

102 |

98 |

M-24 |

1’’ G |

152 + R |

| M 300 + 100/100 |

785 |

54 |

260 |

102 |

140 |

M-24 |

1’’ G |

152 + R |

| M 300 + 150/100 |

1767 |

24 |

260 |

102 |

185 |

M-24 |

1’’ G |

152 + R |

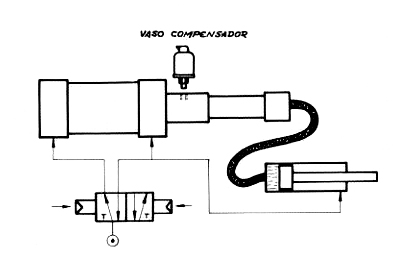

The pressure booster is like a hydraulic plant.

The advantage of the booster is its low cost compared to a hydraulic plant. But it is limited in volume. In other words, in small volumes at high pressure it is much more profitable.

The pressure booster is used with hydraulic cylinders when greater thrust force is required. Clamping pieces in milling machines, jaws, jacks, presses, etc. With short strokes

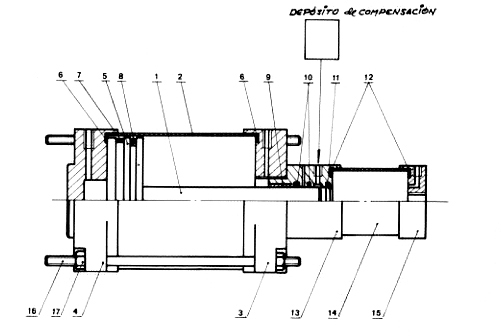

1.- Hard chromium rod

2.- Steel pneumatic tube

3.- Aluminium front cover

4.- Aluminium rear cover

5.- Aluminium piston

6.- Nylon flat seat seal

7.- Nylon piston guide

8.- NBR piston seal

9.- Bronze self-lubricating rod bushing

10.- NBR rod seal

11.- Booster seal up to 450 kgr/cm²

12.- Booster flat seat seal

13.- Steel booster body

14.- Steel booster tube

15.- Steel front booster cover

16.- Steel braces

17.- Brace nuts

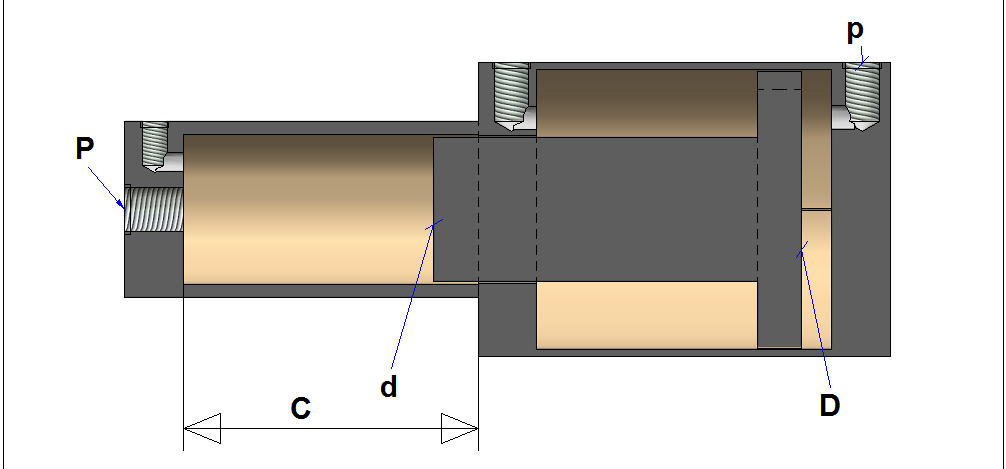

Fill out the following forms and make your own.

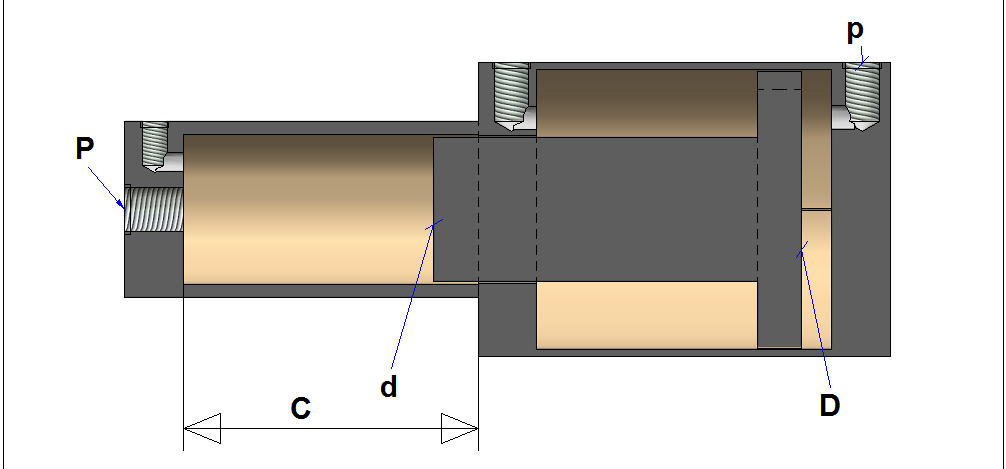

| D (cm) | d (cm) | C (cm) | p (kg/cm2) | Area grande (cm2) | Area pequeña (cm2) | Relac mult | Vol. pequeño (cm3) | Vol grande (cm3) | Presión salida (P - kg/cm2) | Diametro aplicación (cm) | Fuerza salida (kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Presión de entrada (kg/cm2) | Presión de salida (kg/cm2) | Volumen cilindro pequeño (cm3) | Volumen a llenar (cm3) | Volumen de embolada (cm3) | Número de emboladas | 30% Más |

|---|---|---|---|---|---|---|